CA20T 3/4'' Threaded Dust Collector Solenoid Pulse Jet Valve 24VDC 110VAC 220VAC

2 year ago

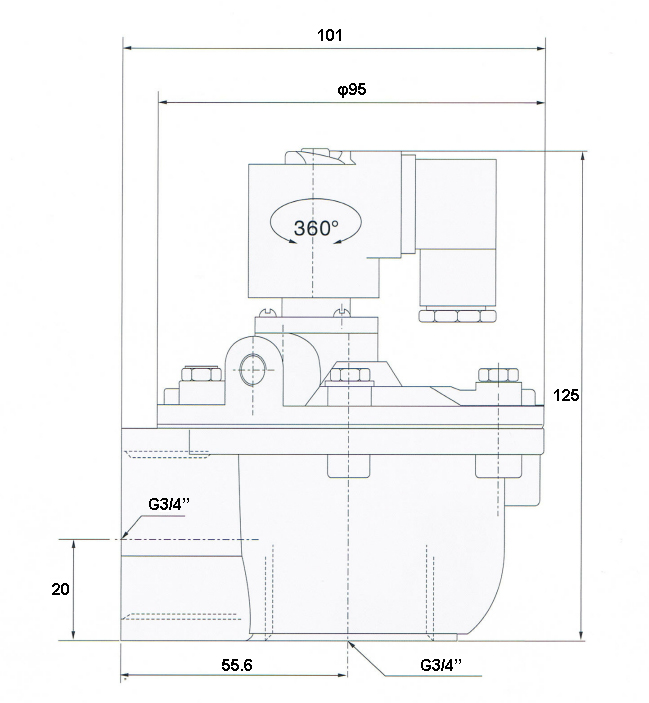

G3/4'' CA20T Pneumatic Pulse Jet Valve

T type CA20T designed for dust collector system with high efficiency and acting of close and open quickly.

3/4 Inch Single Stage Single Nitrile Or Viton Diaphragm Goyen Type Threaded Port Pulse Jet Dust Collector Valve

Description of CA20T

|

CA20T |

|

| Nominal Diameter | φ20 |

| Connection Threed | G3/4'' |

| Voltage | 24V DC,110V 220V AC |

| Volume | 10.1*9.3*12.5cm |

| Working Pressure | 0.3-0.8MPa |

| Medium | Dry Clean Compressed Air |

| Using Age | Injection of 1 million or more |

Working Principle

The diaphragm divides the electromagnetic pulse valve into the front and rear air Chambers. When the compressed air is connected to the rear air chamber through the throttle hole, the pressure in the rear air chamber will press the diaphragm tightly to the valve's output port and the electromagnetic pulse valve will be in the state of "closed". The electromagnetic pulse valve armature is reset when the electrical signal of the pulsed injection control instrument disappears. The vent hole of the rear air chamber is closed. The pressure of the rear air chamber increases, making the diaphragm close to the valve outlet.

The performance test

1. Open voltage test

In the electromagnetic pulse valve inlet air pressure for the nominal pressure access to the clean air, 85% of the nominal input voltage on the electromagnetic valve, width of 0.03 s of electrical signals, check whether the electromagnetic pulse valve open normally.

2, close the pressure test

The inlet of the emp valve is connected with clean air with air source pressure of 0.1mpa, and the electrical signal of the valve is input to check whether the emp valve is closed reliably.

3. Pressure resistance test

Clean air with 0.8mpa air source pressure is connected to the inlet of the emp valve for 60min to check the leakage of air at each sealing part of the emp valve.

4. Insulation resistance test

(1) using the 500 v, the range of 0 m Ω ~ 500 m Ω, precision megohmmeter for level 1, under the condition of the specified environment, measuring electromagnetic coil insulation resistance of casing.

(2) put the valve, temperature humidity box, set the temperature at 35 degrees, relative humidity of 85%, under the condition of applying the 50 hz in the electromagnetic coil with the valve body, sinusoidal ac voltage 250 v, for 1 min, check whether there is a breakdown phenomenon.

5. Vibration resistance test

After the valve is fixed on the vibration test bench, bearing the vibration frequency of 20Hz, the full amplitude of 2mm, which lasts for 30min, check whether the fastener of each part of the valve is loose and whether it works normally.

6. Service life test of diaphragm

The inlet of the electromagnetic pulse valve is connected with clean air of nominal pressure, and the nominal voltage value with width of 0.1s and interval of 3s is input on the electromagnetic pulse valve, and the continuous or cumulative times of operation of the valve are recorded.

Any question just contact us!

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- NINGBO BRANDO HARDWARE CO.,LTD

- *Message:

-

Submit

Main Product:

Solenoid Valve ,

Solenoid Valve Coil,

Solenoid Valve Armature,

Pulse Jet Valve,

Refrigeration Solenoid Valve,

Pneumatic Solenoid Valve