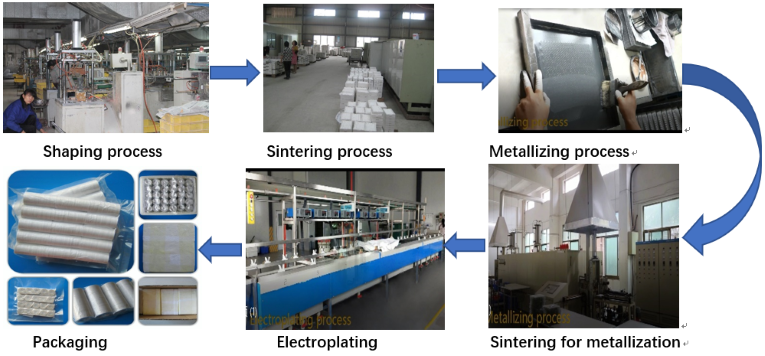

Manufacturing Flow chart for Metalized ceramics

4 year ago

Vacuum Alumina Ceramic Body with Mo/Mn Metallization

With some special requirement in the high vacuum application, only Mo/Mn metallization on ceramic base body is preferred. We can provide thick fiml to thin film via different deposition methods. The molybdenum layer could attached on ceramic body tightly after high-temperature cured.

We are able to manufacture a variety of different specification from small size part to large size metallized ceramic insulators. Based on our comprehensive production equipment from forming to metallization and measured internal inspection devices, we have great advantage in quality and cost control. That's why we are more easier to offer prototyping service with a very small batch in a short lead time.

We offer a wide range of other different technical ceramic components, like general structural ceramic component, ceramic substrate, ceramic seals, ceramic tubes, ceramic grinding burrs and so on.

Technical Key Parameters of metalized ceramic body

|

Leak Rate |

≤1x10-11Pa.m3/s |

Metal Layer Tensile Strength |

≥120Mpa |

|

Volume Resistivity |

≥108Ω•cm |

Coefficient of Thermal Expansion |

(6.5 ~ 8.0) × 10-6 /°C |

|

Insulation Strength |

≥18kV/mm (D•C) |

Dielectric Constant |

9~10(1MHz, 20°C) |

|

Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination |

|||

Main features of metalized ceramic body

● High bonding / brazing strength● Low leakage rate ● High Insulation strength ● High mechanical strength

● Low thermal expansion ● Resistant to corrosion free of rust● Min. electric resistance and vacuum tightness

The application of metalized ceramic body

Widely used in vacuum interrupters, Electron tubes,Gas discharge tube, Vacuum capacitor,Vacuum thyristors,

Surge arresters,Thyristor housings,Diode housings,Power grid tubes,Traveling wave tubes,Insulator rings and cylinder,X-ray tubes and so on

Main Manufacturing Flow Chat

We have a complete comprehensive of production equipment for metallized ceramics from shaping to electroplating.

It helps us to make the dimensional consistency very well. Also, helping us to offer a competitive price.

FAQs(Frequently Asked Questions)

Q 1. Is it available to provide customize products?

A: We could support custom-made demand as per different dimensions, design and metallization and plating.

Q 2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry.

Q 3. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25 working days.

Q 4. What about the transportation and delivery date?

A: Normally we use Int`l express by our forwarder, or with client`s account number. It is about 3~5 working days.

Q 5. How to ensure the quality?

A: The dimension out of any batch will be carried out sampling inspection per International AQL standard. 100% cosmetic inspection will be done.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jinghui Industry Ltd.

- *Message:

-

Submit

Main Product:

Metallized ceramics,

Precision ceramics ,

Pepper Grinder Mechanism,

Ceramic Grinding Mechanism,

Alumina Ceramic Plate,

Ceramic Substrate

You May Also Like