injection molding mold

3 month ago

1. What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used to create parts by injecting molten plastic material into a mold. Once the plastic cools and solidifies, it takes the shape of the mold cavity. This method is ideal for producing large volumes of parts with high precision and repeatability.

2. What Materials Can Be Used in Injection Molding?

A wide range of thermoplastics can be used in injection molding, including ABS, polycarbonate, polypropylene, and nylon, among others. The choice of material depends on the specific requirements of the part, such as strength, flexibility, and resistance to heat or chemicals.

3. How Long Does the Mold Making Process Take?

The time required to create a mold can vary depending on the complexity of the design, the size of the part, and the material used. On average, the mold-making process can take anywhere from a few weeks to several months. It's crucial to work closely with your mold maker to establish a realistic timeline for your project.

4. What Are the Costs Involved in Injection Mold Making?

The costs of injection mold making can be influenced by several factors, including the complexity of the mold, the type of material used, and the number of cavities in the mold. While the initial cost of mold creation can be substantial, injection molding is cost-effective for large production runs due to its low per-unit cost.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Guangzhou One-Stop Engineering Plastics Industries (group) Co., Ltd

- *Message:

-

Submit

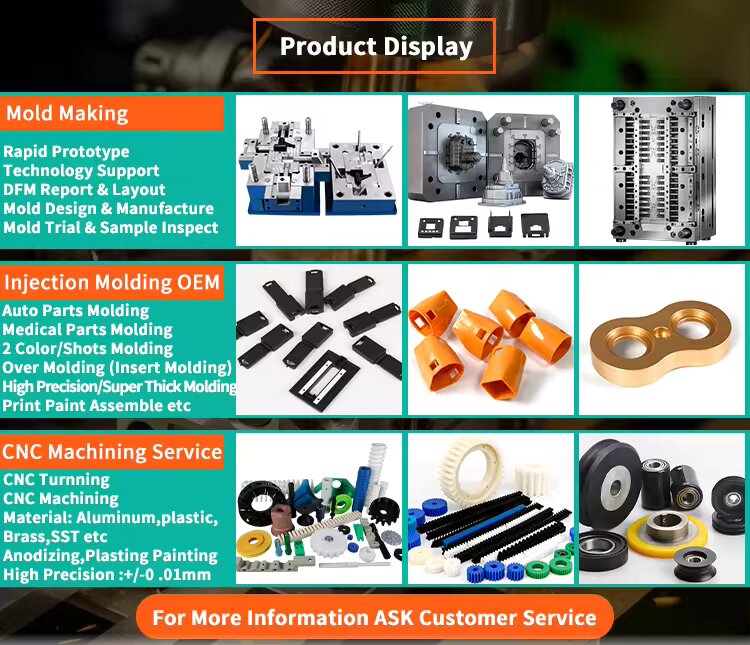

Main Product:

CNC Machining Parts,

Injection Molding Parts ,

Plastic Sheets,

Plastic Tubes,

Plastic Rods,

Peek Sheet