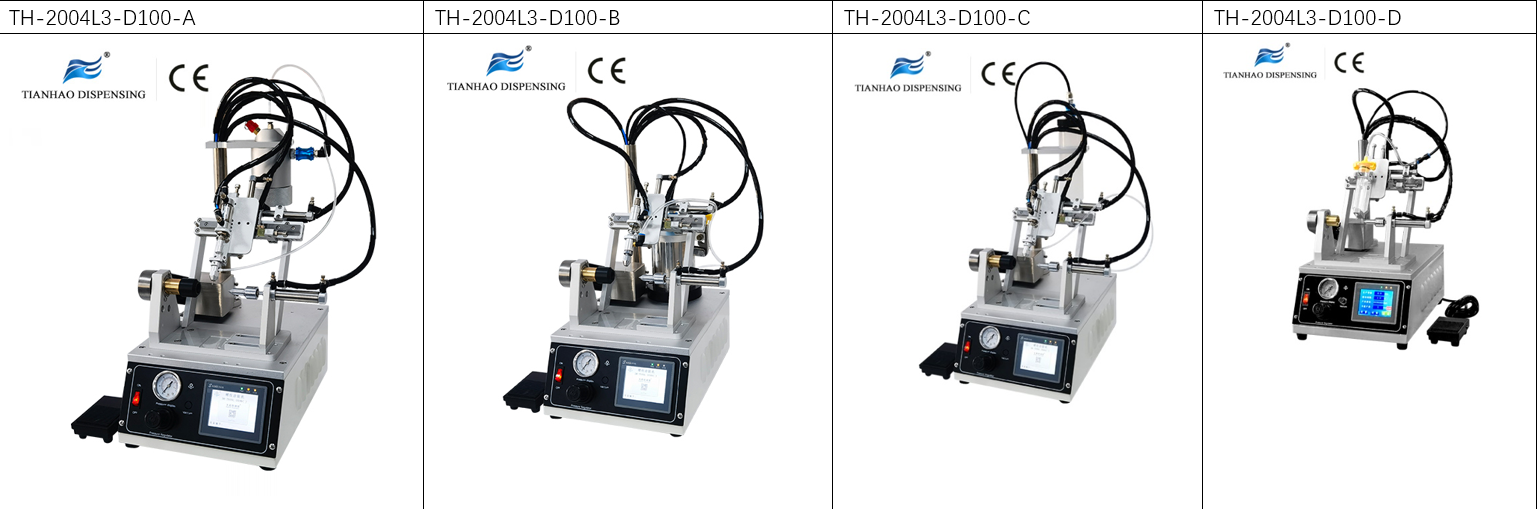

1..The equipment developed and designed for various flat head, mushroom head, hexagon socket and other tiny screws of M1-M3

different of screw,bolt,nut, connector fastener

2. highly sensitive vacuum suction device effectively solves product falling in the coating process.

3. Double-drive design, the product jig and the thimble device are equipped with independent motors to rotate synchronously,

which ensures better concentricity and avoids uneven coating in during rotation proccess.

4. Professionally designed touch screen PLC gluing control system, visual operation panel, all processing parameters can be set

directly through the touch screen, such as the adjustment of gluing start and end positions and gluing length (number of

turns)

5. With external communication function, it can be connected with other devices

6. For different Products should be processed only by changing the product jig

7. It can be matched with different diameter needles according to the size of the workpiece teeth to achieve perfect gluing

effect

8. Equipped with a voltage stabilization control module, dispensing glue evenly, without drawing, dripping, and leaking glue

9.Add optional for automatic unloading device , saving the time of manual unloading and no easy pick and place question.

10.The product be glued product by machine, greatly improves reliability and durability.sealing