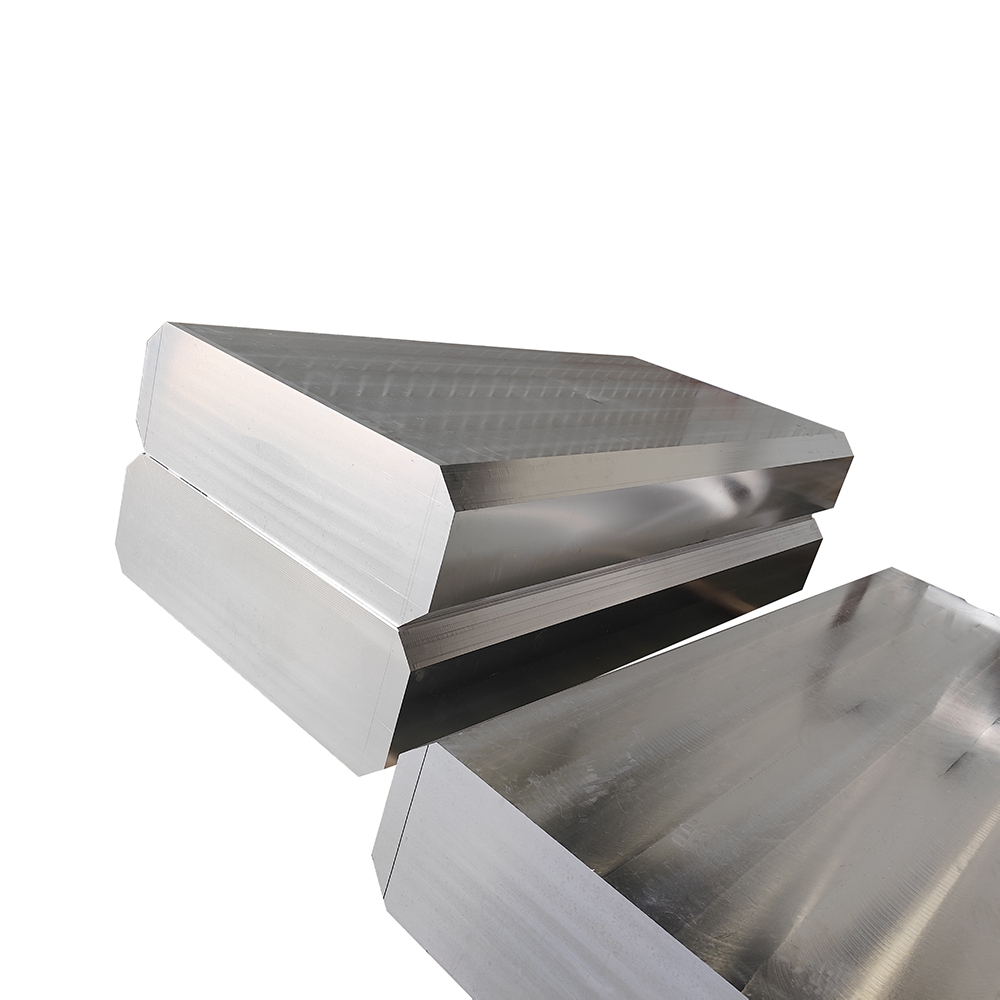

Forging Magnesium Alloy Plate

10 month agoMagnesium alloy has the advantages of high specific strength and specific stiffness, good thermal and electrical conductivity, damping and vibration damping, electromagnetic shielding, easy processing and molding and easy to recycle, etc., in the automotive, electronic communications, aerospace and military defense and other fields with extremely important application value and broad application prospects, known as the "21st Century Green Engineering Materials".

Deformation of magnesium alloy is compared with the casting of magnesium alloy has greater development potential, through the control of the material structure, heat treatment process application, deformation of magnesium alloy can obtain higher strength, better ductility and more diversified mechanical properties, so as to meet the diversified engineering structural components of the application needs. Deformed magnesium alloys often need to be heated to a certain temperature and processed through extrusion, rolling and forging and other hot forming technology. Forging is a process of extruding magnesium alloy.

Forged magnesium alloy is generally carried out at 200-400 ℃. Forging at room temperature is easy to brittle crack, more than 40 ℃ high temperature is due to oxidation and grain size and will have adverse effects. Due to the magnesium alloy forging temperature range is narrower, magnesium alloy thermal conductivity is larger ( about 80 W/m-K ), about 2 times as much as steel, forging contact with the mold cools down very quickly, plasticity decreases, deformation resistance increases, filling performance decreases, so magnesium alloys are more difficult to forge; billet contact area with the mold is larger, the deformation time is longer, so with the contact of the cold mold, very easy to produce cracks, so it is often necessary to mold preheating, preheating temperature is slightly lower than the preheating temperature, the preheating temperature is slightly lower than the preheating temperature, the mold will have adverse effects due to oxidation and grain coarsening. Therefore, it is often necessary to preheat the mold, and the preheating temperature is slightly lower than the billet heating temperature, ranging from 20 to 30 ℃.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Luoyang Maige Magnesium Industry Co., Ltd

- *Message:

-

Submit

Main Product:

magnesium alloy plate,

magnesium alloy rod ,

magnesium alloy wire,

magnesium profile,

magnesium ingot,

magnesium alloy sheet

You May Also Like