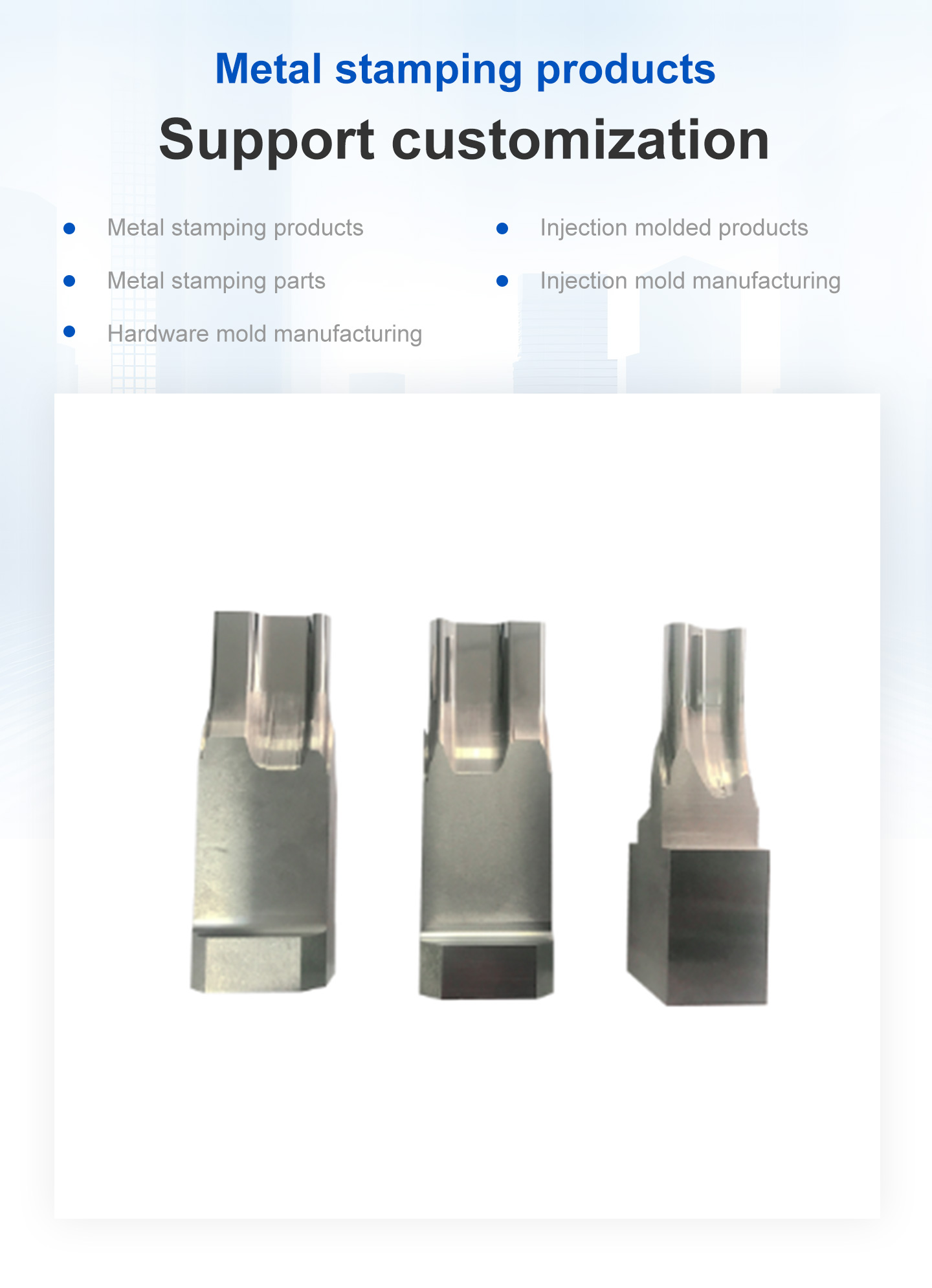

Carbide Punches

7 month agoWhat are the precautions for Carbide Punches?

1. Precision and tolerance:

The dimensional accuracy and shape accuracy of the Carbide Punch and Die have a direct impact on the quality of the stamped parts, so the tolerances need to be strictly controlled in the manufacturing process to ensure the dimensional consistency and surface quality of the stamped parts.

2. Matching and guiding:

The Carbide Stamping Dies are usually used in conjunction with the lower die (concave die), and the accurate alignment of the punch and the lower die during the stamping process is ensured by precise guiding systems, such as guide bushings and guide pillars.

3. Design and Manufacturing:

The design of Carbide Punches need to consider factors such as the nature of the material, stamping process, punch life and maintenance costs. Precision machining technology, such as CNC machining, is used in the manufacturing process to ensure the shape and dimensional accuracy of the punch.

4. Maintenance and upkeep:

Regularly check the wear and tear of punches, and replace punches with serious wear and tear in time to avoid affecting the quality of stamped parts. At the same time, keep the punch clean to avoid impurities from entering and reduce wear and tear.

5.Application industry:

Mold punches are widely used in many industries such as automotive, electronics, aerospace, home appliances, packaging, machinery manufacturing, etc. It is an important tool to achieve precision machining of sheet metal, plastics, rubber and other materials.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Hao Chen Precision Industry Co., Ltd.

- *Message:

-

Submit

Main Product:

Hardware Mold ,

Hardware Stamping Parts,

Injection Molded Products,

Carbide Punches,

Mold Parts,

Injection Mold Manufacturing