Lifetime Carbide Punch and Die Set

7 month agoAs an important part of the mold, its design, material selection, manufacturing process, and maintenance must be strictly controlled to meet the needs of efficient, high-precision production.

How accurate is the Mould Trim Line?

The manufacture of Mould Trim Line heads requires high-precision machining techniques, such as wire cutting, electric discharge machining (EDM), and laser cutting, to ensure the sharpness of the cutter head edges and the accuracy of the dimensions to meet the requirements of high-precision machining.

Application Areas:

Insert Injection Molding Process is widely used in many fields such as Metal Stamping Dies, plastic molding, packaging material cutting, electronic component manufacturing, automotive parts production, etc. It is an important tool to ensure product accuracy and production efficiency.

How to maintain and care for the Insert Molding Process?

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Hao Chen Precision Industry Co., Ltd.

- *Message:

-

Submit

Main Product:

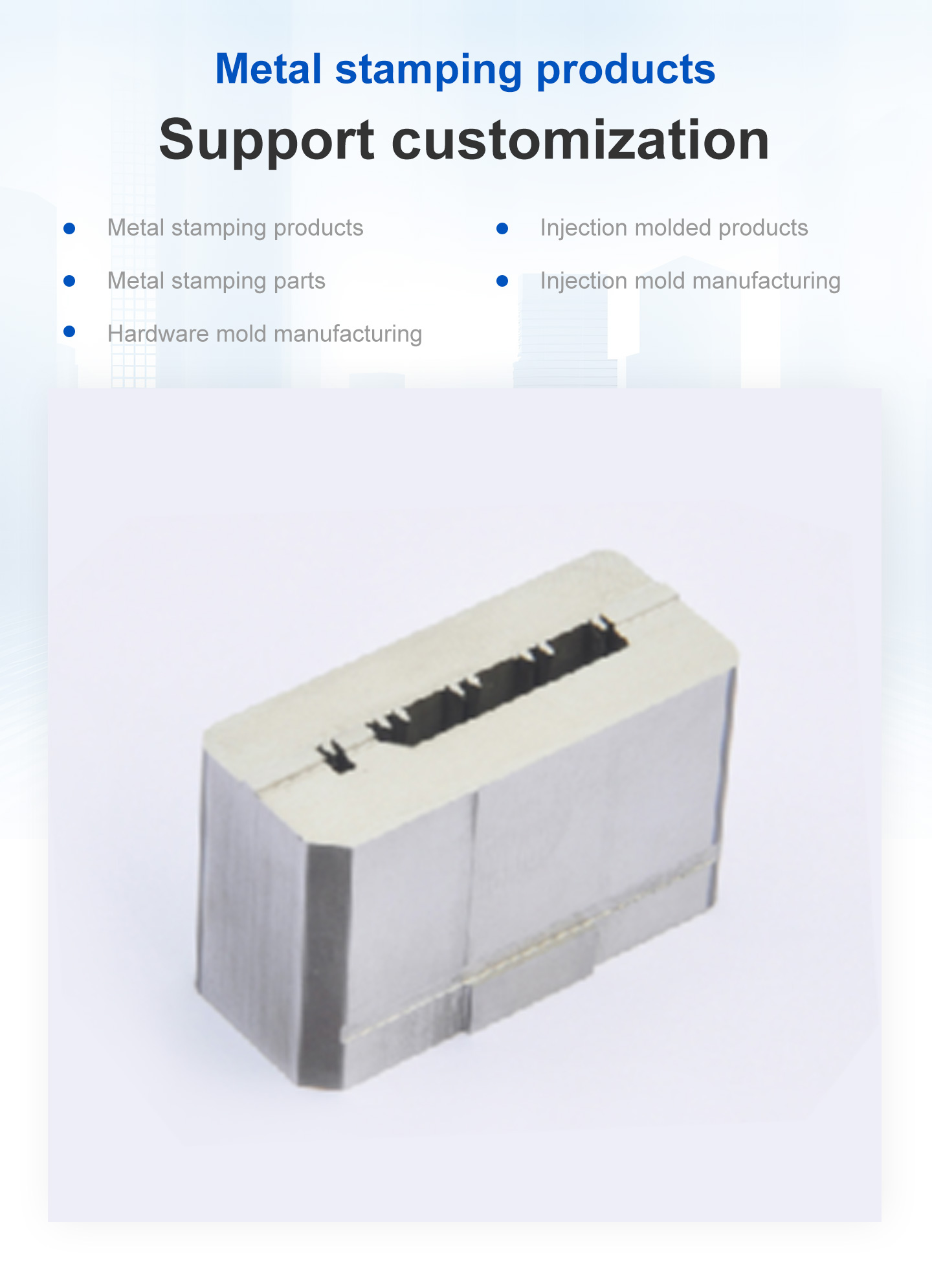

Hardware Mold,

Hardware Stamping Parts,

Injection Molded Products ,

Carbide Punches,

Mold Parts,

Injection Mold Manufacturing