Manual plate valve

4 month agoBasic structure:

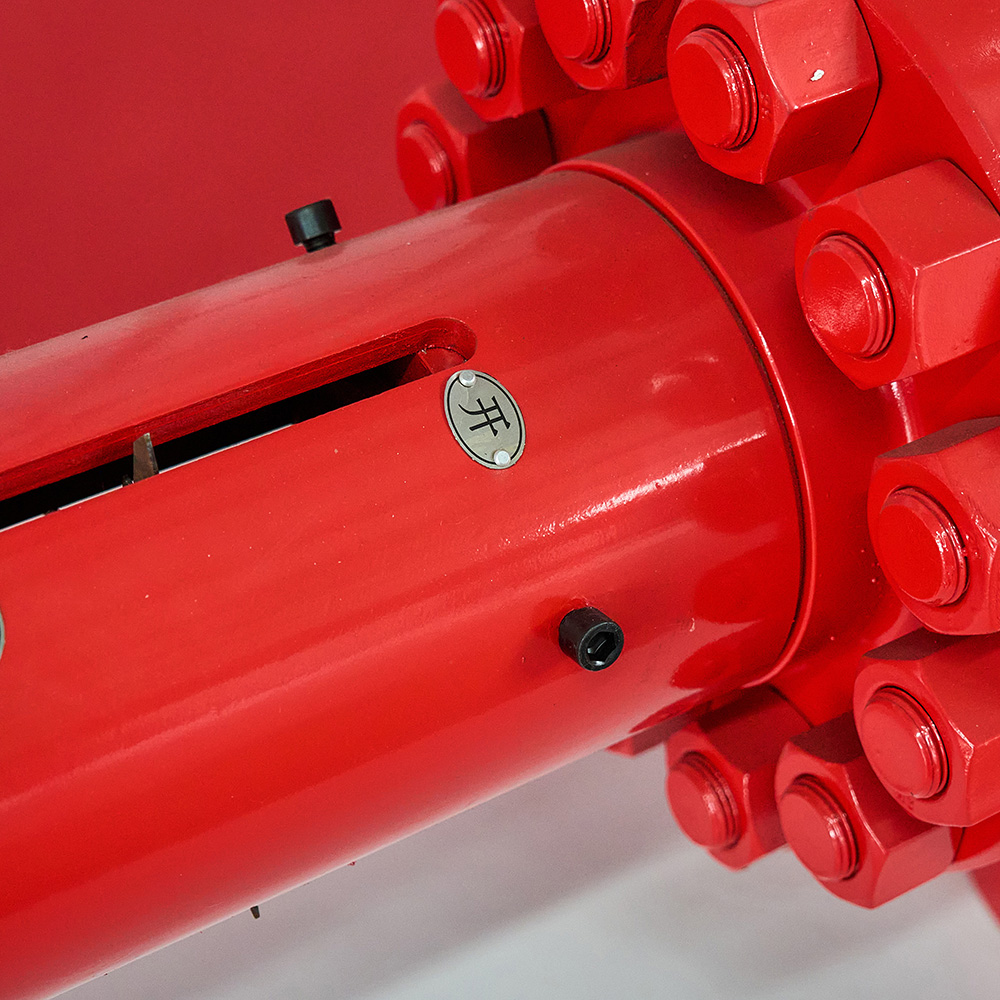

Usually composed of a valve body, a valve cover, a valve core (or valve disc), a seal, and an operating mechanism.

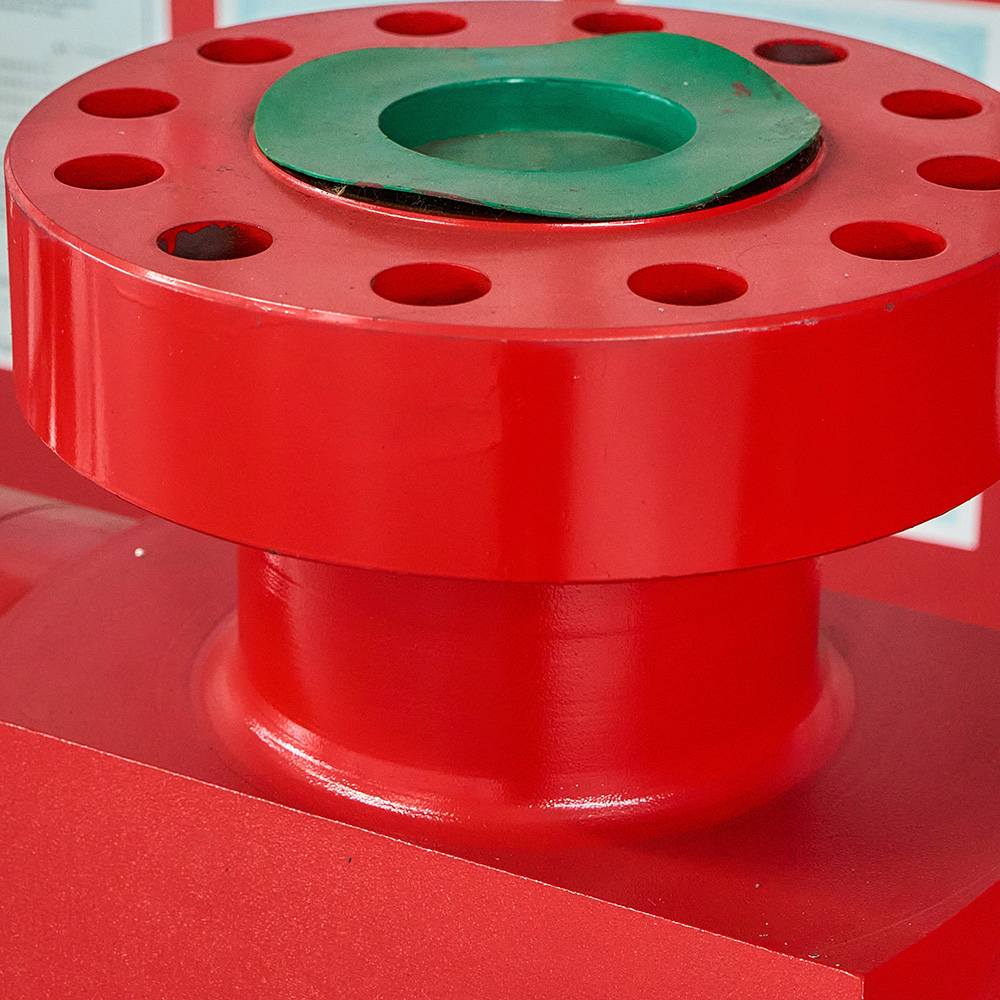

Valve body: It is the main part of the valve, used to accommodate the valve core and seal, withstand the pressure of the fluid in the pipeline, and provide support and installation foundation for other parts of the valve. Its shape and size vary according to the type and use requirements of the valve.

Valve cover: It is used to fix the valve core and seal. It is usually tightly connected to the valve body through bolts, nuts and other connectors. It may also have a sealing function to prevent the medium from leaking from the connection between the valve body and the valve cover.

Valve core (or valve disc): It is the core component of the valve, used to control the on-off and flow of the fluid. Its structural forms are diverse, such as spherical, conical, disc-shaped, etc. It changes the relative position with the valve seat by rotating, lifting or sliding, thereby realizing the opening, closing and adjustment functions of the valve.

Seals: installed between the valve core and the valve seat and at the connection between the valve body and the valve cover to prevent medium leakage. Common sealing materials include rubber, polytetrafluoroethylene, metal, etc., and their performance directly affects the sealing effect of the valve.

Operating mechanism: used to manually or automatically drive the valve core to move and realize the control function of the valve. Common operating mechanisms include handwheels, handles, levers, sprockets, gears, worm gears, electric devices, pneumatic devices, hydraulic devices, etc.

Main functions:

Cut-off function: It can completely cut off the flow of fluid and stop the transmission of fluid in the pipeline. It is often used in occasions where the pipeline system or equipment needs to be isolated. For example, when repairing or replacing equipment or pipelines, closing the corresponding valve can prevent fluid leakage and ensure safe operation.

Adjustment function: The flow rate of the fluid can be adjusted as needed. By changing the opening of the valve core to control the resistance of the fluid passing through the valve, the flow rate can be accurately controlled. It is often used in process processes that require control of fluid flow, such as flow ratio in chemical production and hot water flow regulation in heating systems.

Diversion function: Change the flow direction of the fluid so that the fluid flows along a predetermined route. In a complex piping system, the diversion function of the valve can achieve fluid distribution, confluence or diversion to meet different process requirements.

Check function: Prevent fluid backflow, open automatically using the fluid's own kinetic energy, and automatically close when the reverse flow occurs. It is often installed at the outlet of the water pump, the outlet of the steam trap, and other places where the fluid does not allow reverse flow. For example, in the water supply and drainage system, the check valve can prevent water backflow and protect water pumps and other equipment from the influence of reverse pressure.

Diversion function: Divide a fluid into multiple streams, or merge multiple streams into one stream. It is often used in situations where fluids need to be distributed or mixed. For example, in an air-conditioning system, the refrigerant can be distributed to different evaporators through a diversion valve.

Overflow pressure relief function: When the pressure in the system exceeds the set value, the valve can automatically open and discharge the excess fluid to protect the safety of the system. For example, the safety valve will automatically open when the pressure in the pipeline or equipment is too high to release the pressure and prevent accidents such as explosions.

If you need, please contact us.

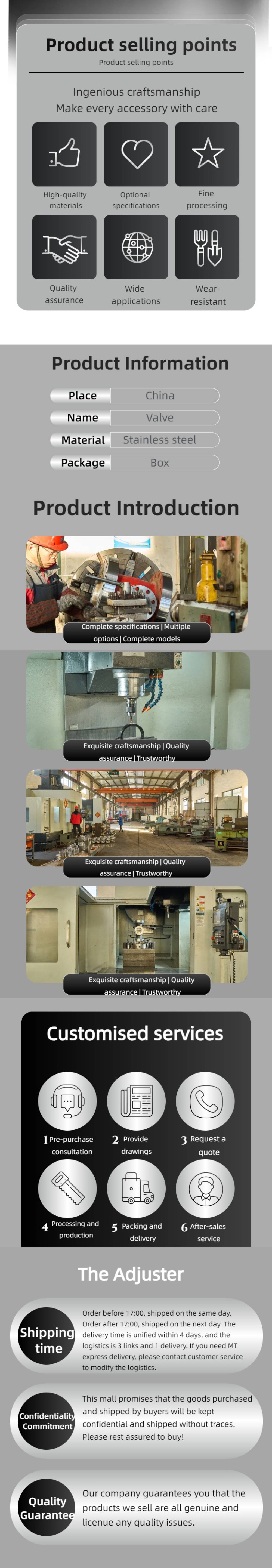

| Product name | valve |

| Specification model | 5 1/8 |

| Implementation standard | API 6A |

| Rated working pressure | 15000PSi |

| Product specification level | PSL1~PSL3G |

| Product performance level | PR1~PR2 |

| Temperature level | PU, LU |

| Material level | AA~FF |

| Product color | red |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jianhu Fulida Machinery Manufacturing Co. , Ltd.

- *Message:

-

Submit

Main Product:

Oilfield wellhead device,

Drilling and production equipment valve,

Blowout preventer ,

Fracturing Manifold,

Forged steel flange,

Forged parts of wellhead manifold

You May Also Like