Double head bundling machine

10 month agoHow does a dual-head strapping machine for steel coils operate?

A dual-head strapping machine for steel coils automates the process of securing steel coils with strapping material.

General Operation:

1. Coil Loading: The steel coil is loaded onto a conveyor or turntable depending on the machine design.

2. Positioning: The coil is positioned automatically or manually based on the machine's configuration.

3. Strapping Head Movement: One or both strapping heads (depending on the chosen cycle) move their arms with the strapping material towards the coil.

4. Strap Feeding and Tensioning: The strapping material is fed from a dispenser and automatically tensioned to a pre-set level. This ensures the coil is secured tightly.

5. Sealing and Cutting: The strap ends are fed into the sealing unit (friction weld, ultrasonic weld, etc.) to create a secure joint. The excess strap is then automatically cut.

6. Completed Coil: The strapped steel coil is unloaded from the machine, ready for further processing or transport.

Dual-Head Specifics:

1. Double the Speed: The main advantage of a dual-head machine is its ability to apply two straps simultaneously. This can significantly increase the strapping speed compared to a single-head machine.

2. Independent or Simultaneous Operation: Some dual-head machines can operate each head independently, allowing for single or double strap applications. Others might only operate in a simultaneous mode, applying both straps at once.

3. Head Configuration: The strapping heads can be positioned on the sides or top of the machine, depending on the design and chosen strapping pattern (horizontal or vertical).

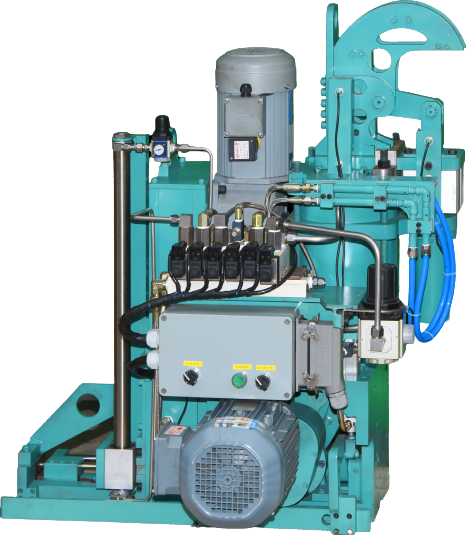

Parameters of strapping machine head DGR-IVA(Q)

|

DGR-IVA(Q)

Fully Automatic Pneumatic Tensioning Buckle Type Steel Belt Strapping Machine Head |

|

| Power Source | Daily Maintenaance |

| Voltage: AC380V Belt feeding motor: 2.2kw Logic motor: 1.1kw Reduction Ratio: 1:120 Pneumatic parts: Tensioning cylinder, holding-belt cylinder, pressing-belt-wheel cylinder, pressing-buckle cylinder, feeding-buckle cylinder. Pressure: 4-6bar Instantaneous gas consumption: Max 0.9L/s |

As per general equipment maintenance |

| Strapping Speed | Belt Spec |

| General working time of head in strapping process is 9.8 secs/belt. | Width: 19mm, 25mm,32mm, Thickness: 0.8-1.2mm |

| Steel Belt Connection | Applicable Environment |

| Buckle connection Maximum quantity of lock installed on the machine at a time is 200 pieces. |

Hyperthermal environment, normal temperature environment, low environment, and various complex environment. |

| Belt tension | Applicable Objects |

| Max.20000N (adjustable) | Hot rolled coil, hot rolled plate, high-strength steel, cold rolled coil, ingot pile, overweight pipe pile, bar pile, and various overweight material. |

| Consumable Accessories List | Strength of Steel Belt Joint |

| Feeding-belt wheel, belt cutter, biting unit. | The connection strength accounts for about 75% of the steel belt itselt(influenced by the toughness and rigidity of the steel belt, compressive strength, and buckle quality). |

| Machine Maintenance | |

| Suggest providing minor maintenance every 6 months and major maintenance 1 year. | |

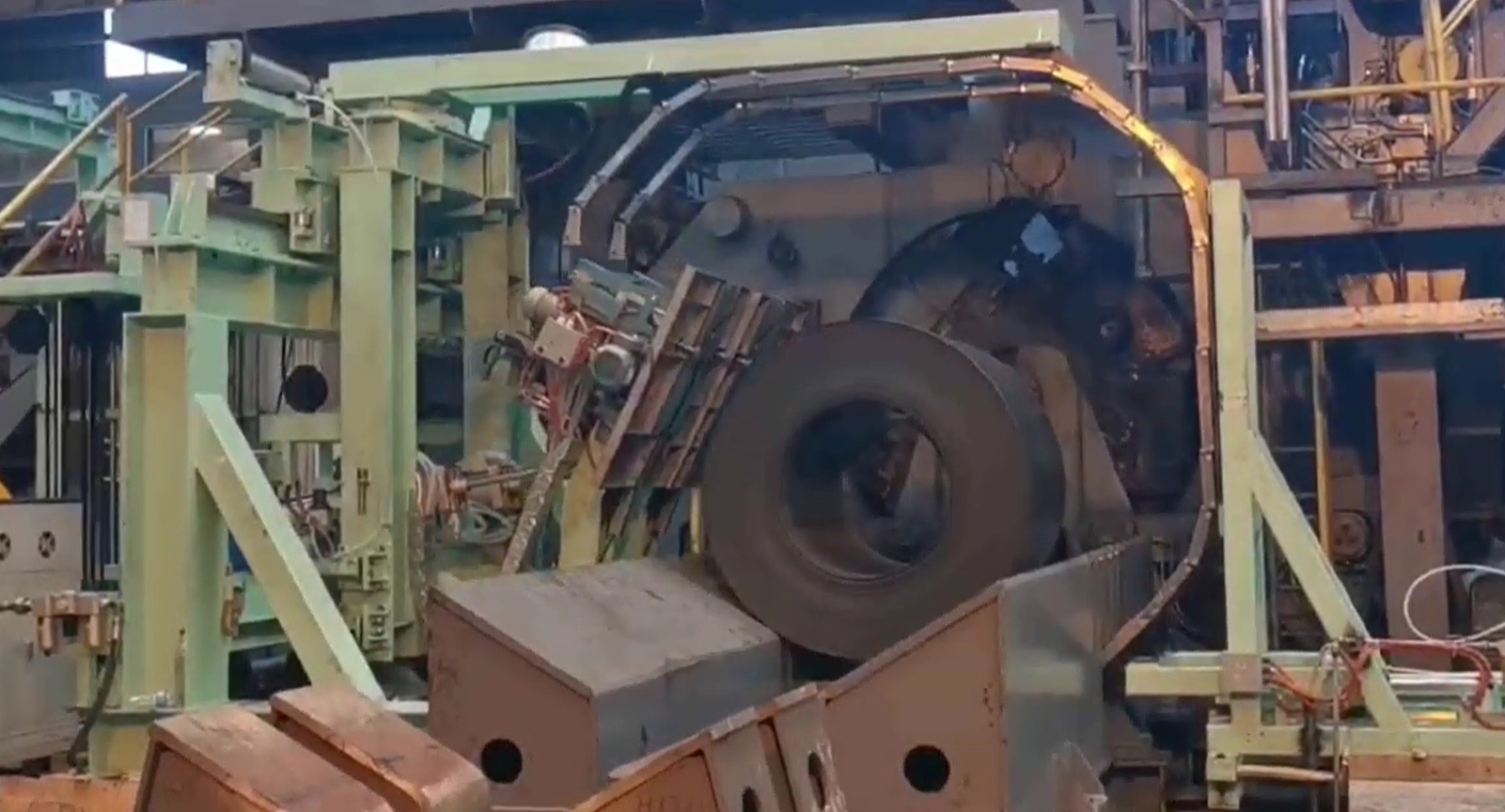

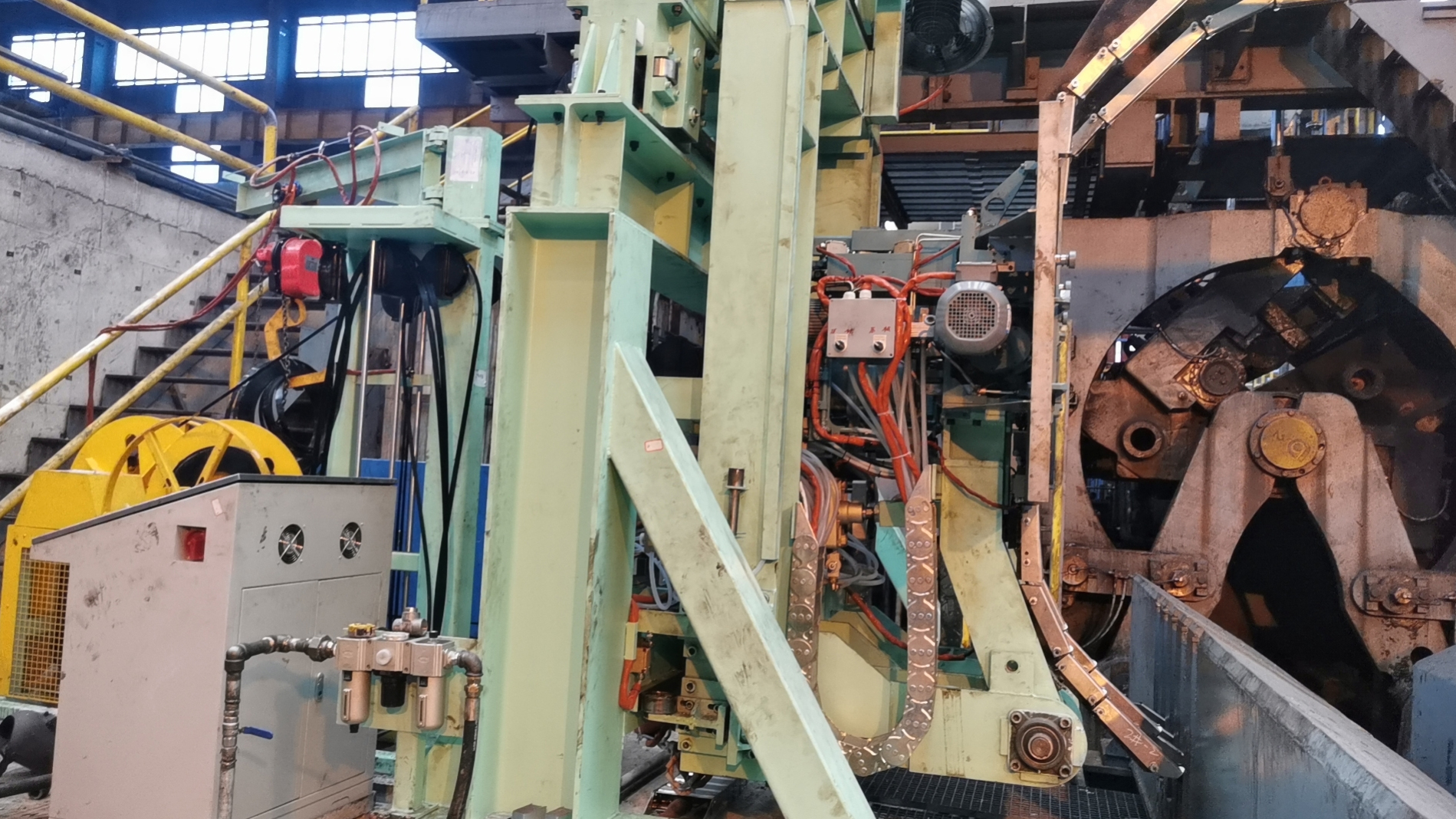

The strapping process of dual-head strapping machine for steel coils:

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen Packway Technology Development Co., LTD

- *Message:

-

Submit

Main Product:

electric actuator,

hydraulic cylinder,

coil strapping machine ,

Steel coil production and packaging unit,

Fully automatic steel pipe stacking production and,

equipment and system solutions for steel coil logi

You May Also Like