machine head tightening test

10 month agoSuperworker's main products and service include: fully automatic mechanical equipment(steel belt/PET belt strapping machine, stripping machine,marking machine, labeling machine, etc), intelligent industrial packaging units(coil material, linear material, board material, etc), intelligent coil material logistics system, similar product's renovation and upgrading, maintenance service, and supply of vulnerable and consumable parts

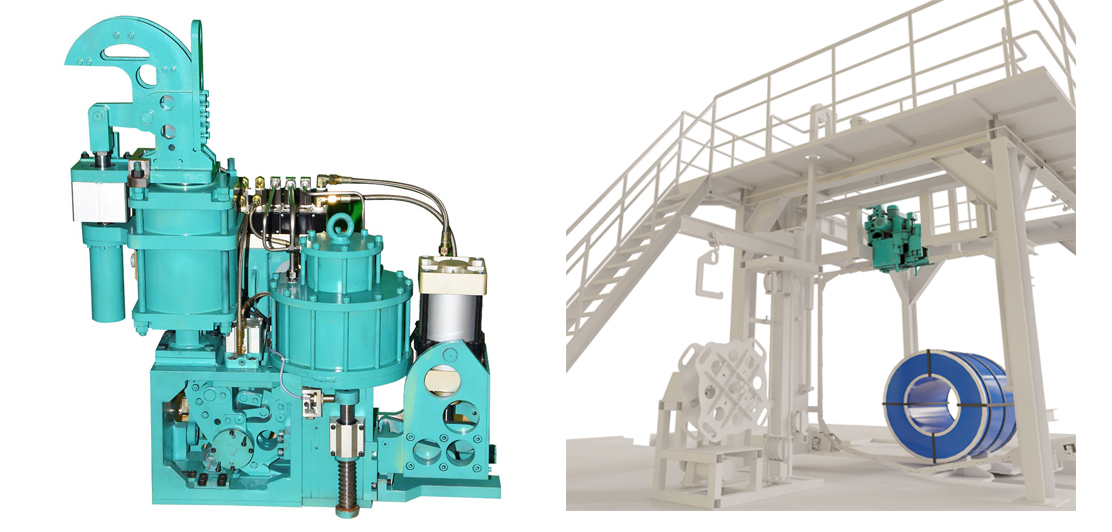

Aluminium/Copper soft metal belt(30mm, 1.25mm) strapping machine for aluminium coils/ingots/rods, copper coils/ingots/rods(Exclusive version)

Parameters of the special soft metal belt strapping machine

|

DGR-IIC(Q)Type

Aluminium and Copper Belt and Other Special Soft Material Belt Strapping Machine Head |

|

| Power Source | Daily Maintenance |

| Voltage: 380V Belt feeding motor: 2.2kw Logic motor: 1.1kw Pneumatic parts: tension cylinder, holding-belt cylinder, pressing-belt-wheel, half-biting cylinder, full-biting cylinder, anti-loosening cylinder, flanging cylinders Pressure: 4-6bar Instantaneous gas consumption: Max 0.9L/s |

As per general equipment maintenance |

| Strapping Speed | Aluminium(Copper) Belt Spec |

| General working time of head in strapping process is 9.8 secs/belt. | Width: 30mm, Thickness: 1.25mm |

| Aluminium(Copper) Belt Connection | Applicable Environment |

| Biting without buckle(with anti-loosening function) | Normal temperature environment, low temperature environment, and various complex environment. |

| Aluminium(Copper) Belt tension | Applicable Objects |

| Max.15000N (adjustable) | Aluminium coil, aluminium ingot pile, aluminium rod, copper coil, copper ingot pile, copper rod. |

| Consumable Accessories List | Steel Belt Connection Strength |

| Belt cutter, Biting unit | The strength of connecting point accounts for about 65% of the aluminium(copper) belt itself (influenced by the mechanical properties of the aluminium(copper) belt. |

| Machine Maintenance | |

| Suggest providing minor maintenance every 6 months and major maintenance 1 year. | |

Strapping Machine Head Manufacturing Center

The machine heads are made in Shenzhen, China, all core components are manufactured by international standards. Before leaving the factory, all machine heads and complete strapping machines will be strictly inspected and tested, to ensure the best quality.

Superworker strapping machine combines domestic and international technology.

- Leveraging Expertise: By incorporating international technology, Superworker has utilized advancements and innovations from leading strapping machine manufacturers worldwide. This give us a competitive edge in terms of features and performance.

- Adapting to Local Needs: At the same time, by integrating domestic technology, we are tailoring our machines to better suit the specific needs and preferences of the Chinese market.

- Stronger Overall Offering: The combination of international technology and domestic know-how potentially result in strapping machines that are both cutting-edge and well-suited to the Chinese market and overseas markets.Qualified with Certificates

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen Packway Technology Development Co., LTD

- *Message:

-

Submit

Main Product:

electric actuator,

hydraulic cylinder,

coil strapping machine,

Steel coil production and packaging unit ,

Fully automatic steel pipe stacking production and,

equipment and system solutions for steel coil logi

You May Also Like