32mm plate strapping machine

9 month agoHow does DGR-IIB(Q) finish the strapping?

This strapping machine bundles materials by steel belt(Width: 19mm/25mm/32mm; thickness: 0.8-1.2mm), tightens the belt by pneumatic tensioning, joints punching force. When the steel belt is tightened well, the machine will punch 3 pairs of opposite buttons on the steel belt, then promotes the opposite buttons to overlap, finally fold two sides of the steel belt. These actions can not only increase joint strength, but also prevent buttons off. That is how the strapping machine head works. By above steps, the strapping machine strap the belt one by one.

Technical Parameters of DGR-IIB(Q) strapping machine:

|

DGR-IIB(Q)

Fully Automatic Pneumatic Tensioning Steel Belt Strapping Machine Head with Anti-loosening and No Buckle |

|

| Power Source | Daily Maintenaance |

| Voltage: AC380V Belt feeding motor: 2.2kw Pneumatic parts: Tensioning cylinder, holding-belt cylinder,pressing-belt-wheel cylinder, half-biting cylinder, full-biting cylinder, anti-loosening cylinder, flanging cylinders Pressure: 4-6bar Instantaneous gas consumption: Max 0.9L/s |

As per general equipment maintenance |

| Strapping Speed | Belt Spec |

| General working time of head in strapping process is 12.8 secs/belt. | Width: 19mm, 25mm,32mm, Thickness: 0.8-1.2mm |

| Steel Belt Connection | Applicable Environment |

| By stamping three pairs of buckles on the steel belt, fold the edges on both sides after the buckles overlap(for increasing the connection force, and prevent the buckle loosening). | Hyperthermal environment and various complex environment. |

| Belt tension | Applicable Objects |

| Max.20000N (adjustable) | Hot rolled coils, hot rolled plates, galvanized coils, cold rolled coils, steel pipe piles, bar piles, plate piles, aluminium ingot piles, steel ingot piles, pipe piles, wood piles, waste piles, etc. |

| Consumable Accessories List | Strength of Steel Belt Joint |

| Feeding-belt wheel, tensioning wheel, belt cutter, biting unit, loose-proof top grain, loose-proof bottom grain, biting unit. | The strength of connecting point accounts for about 65%-75% of the strength of the steel belt itself (influenced by belt's rigidity, toughness, and tensile strength.) |

| Machine Maintenance | |

| Suggest providing minor maintenance every 6 months and major maintenance 1 year. | |

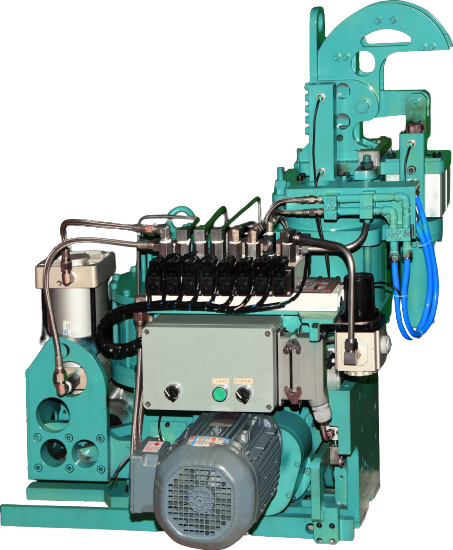

DGR-IIB(Q) strapping machine head image:

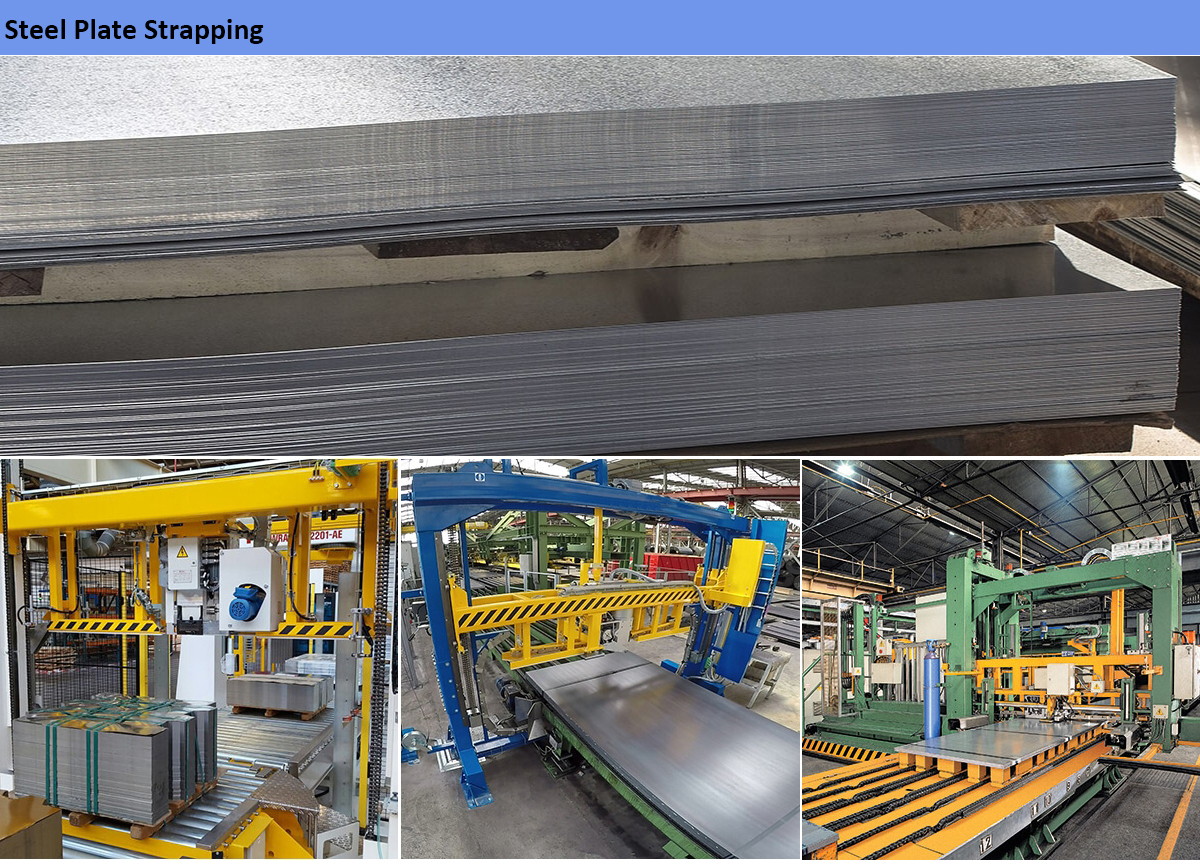

Inlay on gantry strapping machine frame to strap steel sheets/plates:

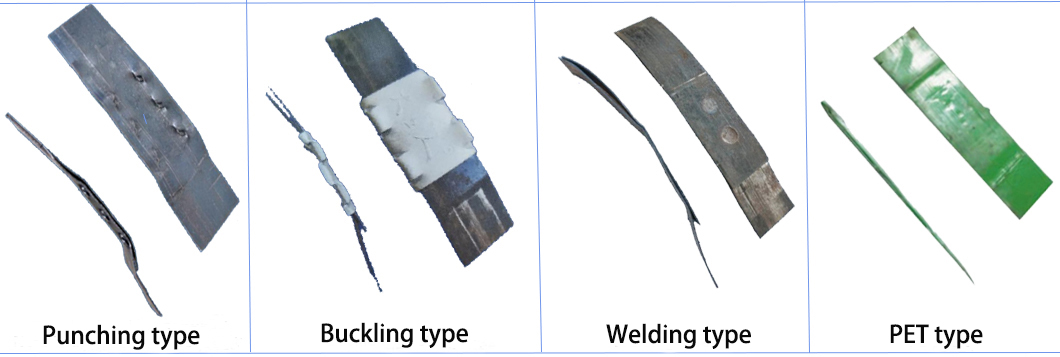

Superworker strapping belt types:

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen Packway Technology Development Co., LTD

- *Message:

-

Submit

Main Product:

electric actuator,

hydraulic cylinder,

coil strapping machine,

Steel coil production and packaging unit,

Fully automatic steel pipe stacking production and,

equipment and system solutions for steel coil logi

You May Also Like