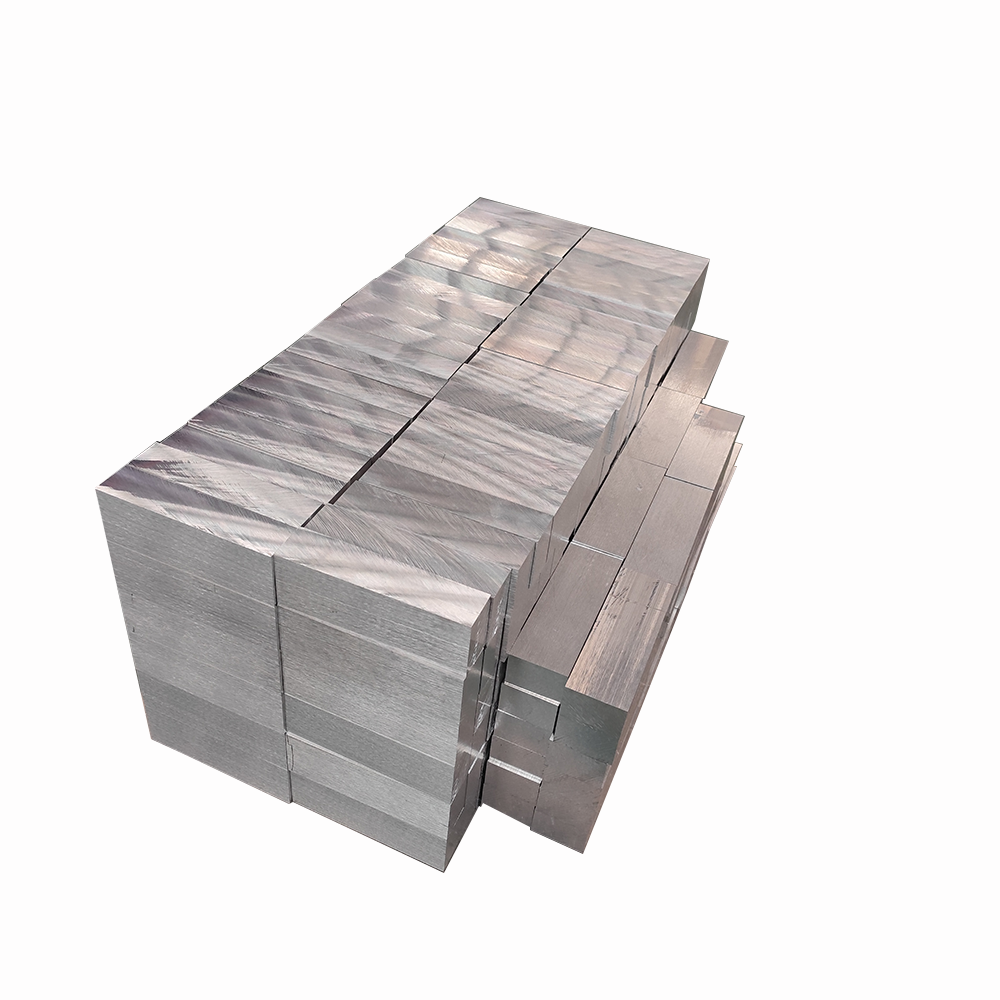

Casting Magnesium Alloy Plate

9 month agoOur Magnesium Alloy Casting Plate meets the highest quality and performance standards and offers great workability and versatility. Designed for the aerospace, automotive, and manufacturing industries, it offers an excellent surface finish, good thermal conductivity, and lightweight properties. It is ideally suited for the manufacture of complex components that require both precision engineering and the maintenance of structural integrity.

Magnesium alloy cast plate is manufactured using advanced casting techniques to ensure a uniform grain structure and a high strength-to-weight ratio. Its machinability allows for complex designs without compromising durability. Magnesium alloy cast plate is also superbly resistant to corrosion and is suitable for use in harsh environments. Cast magnesium alloy plate also has precise dimensional tolerances, making it ideal for applications that require precise specifications.

Magnesium alloy cast plate is designed with a focus on providing optimum performance for a variety of industrial sectors. The cast plate features a proprietary alloy formulation that provides excellent machinability for efficient cutting, drilling, and milling operations. Its lightweight properties reduce overall system weight and improve fuel efficiency in automotive and aerospace applications. The superior thermal properties of magnesium sheet make it ideal for heat exchangers and electronics housings.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Luoyang Maige Magnesium Industry Co., Ltd

- *Message:

-

Submit

Main Product:

magnesium alloy plate,

magnesium alloy rod ,

magnesium alloy wire,

magnesium profile,

magnesium ingot,

magnesium alloy sheet

You May Also Like