Magnesium Profiles

9 month ago

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Luoyang Maige Magnesium Industry Co., Ltd

- *Message:

-

Submit

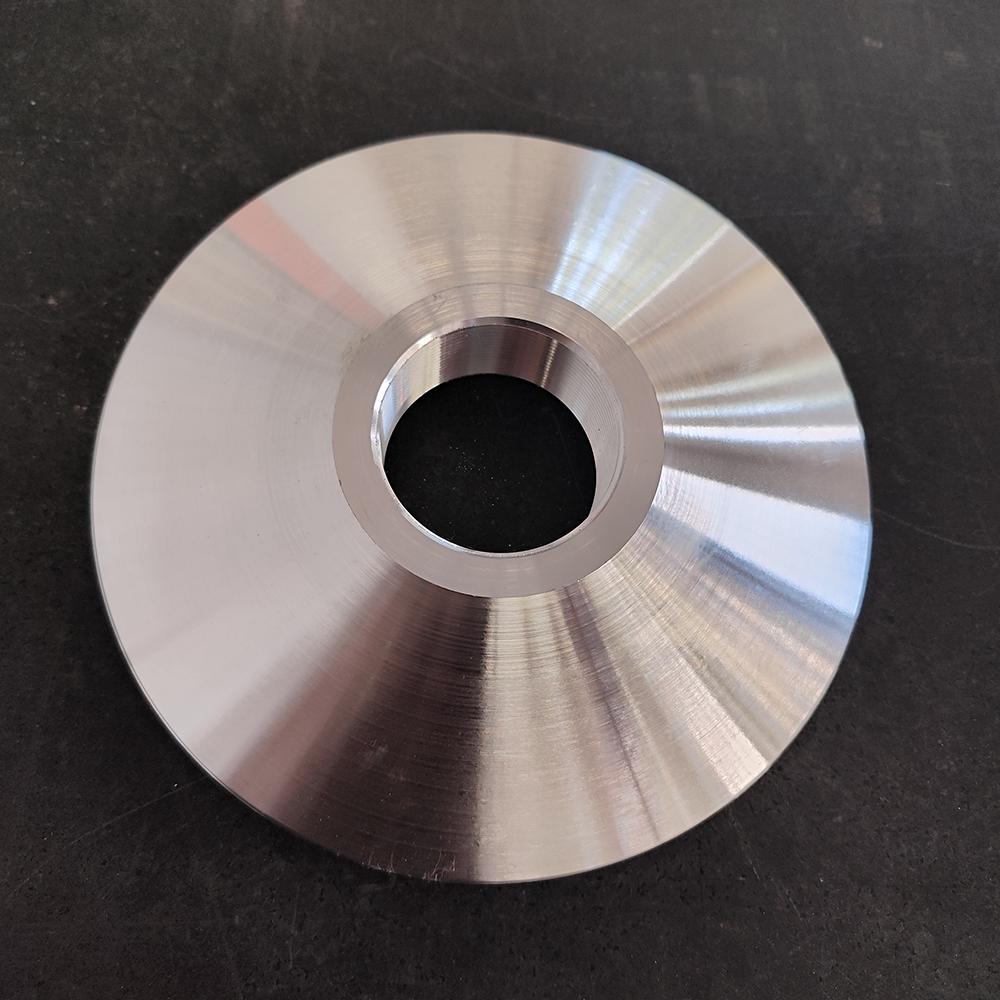

Main Product:

magnesium alloy plate,

magnesium alloy rod,

magnesium alloy wire,

magnesium profile ,

magnesium ingot,

magnesium alloy sheet

You May Also Like