Hydraulic plate valve

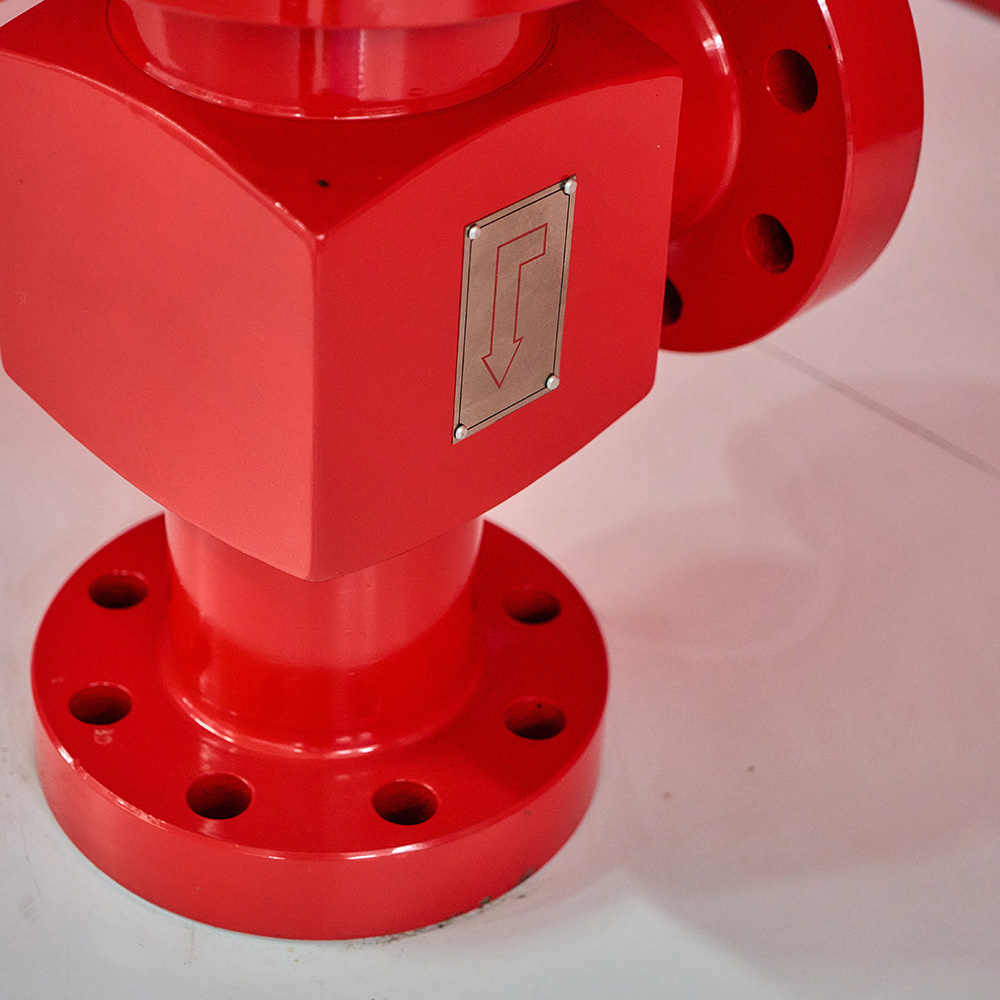

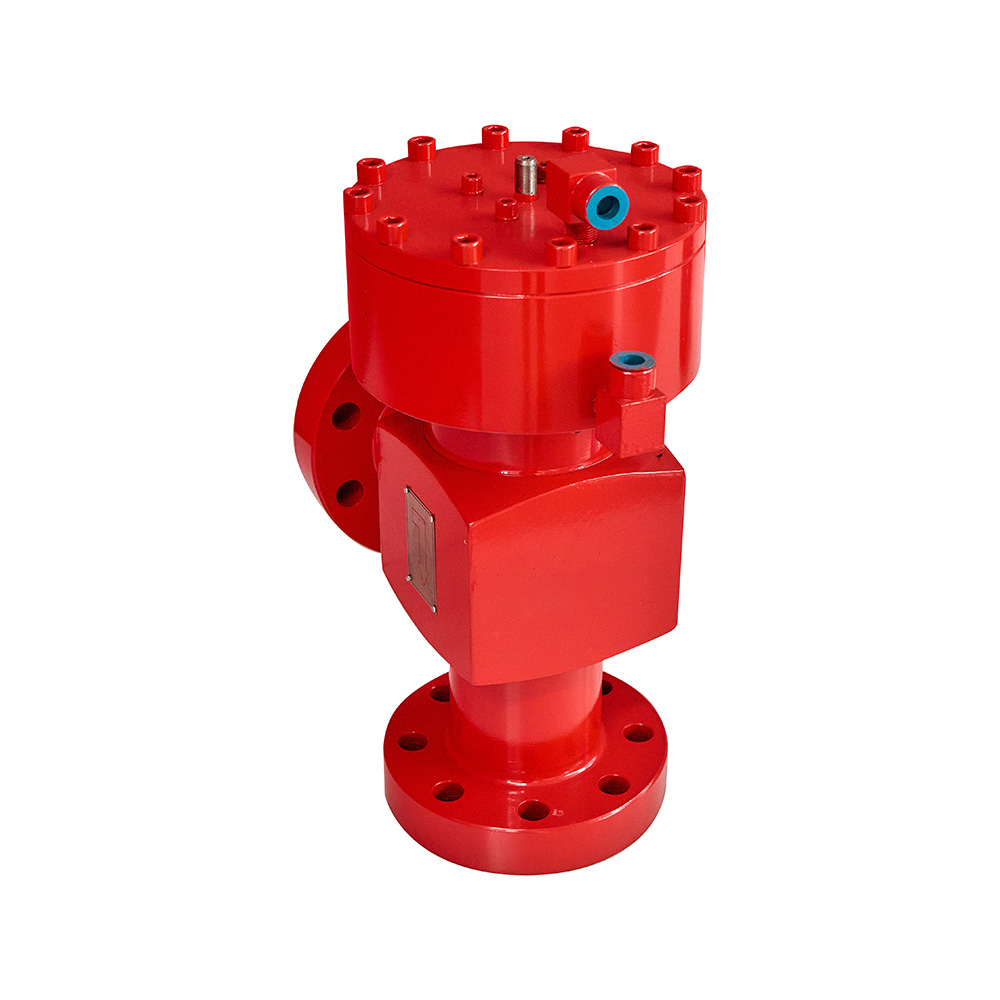

4 month agoThe hydraulic throttle valve is mainly composed of a valve body, a valve core, a valve seat, a hydraulic cylinder, a piston, a valve stem and a valve position transmitter. The valve core is usually cylindrical and made of hard alloy as a whole; the inner ring of the valve seat is also inlaid with hard alloy; the valve cover and the medium contact end are welded with hard alloy, which has good wear resistance and corrosion resistance. A nylon wear-resistant bushing is embedded in the outlet channel of the valve to protect the valve body from wear.

Working process

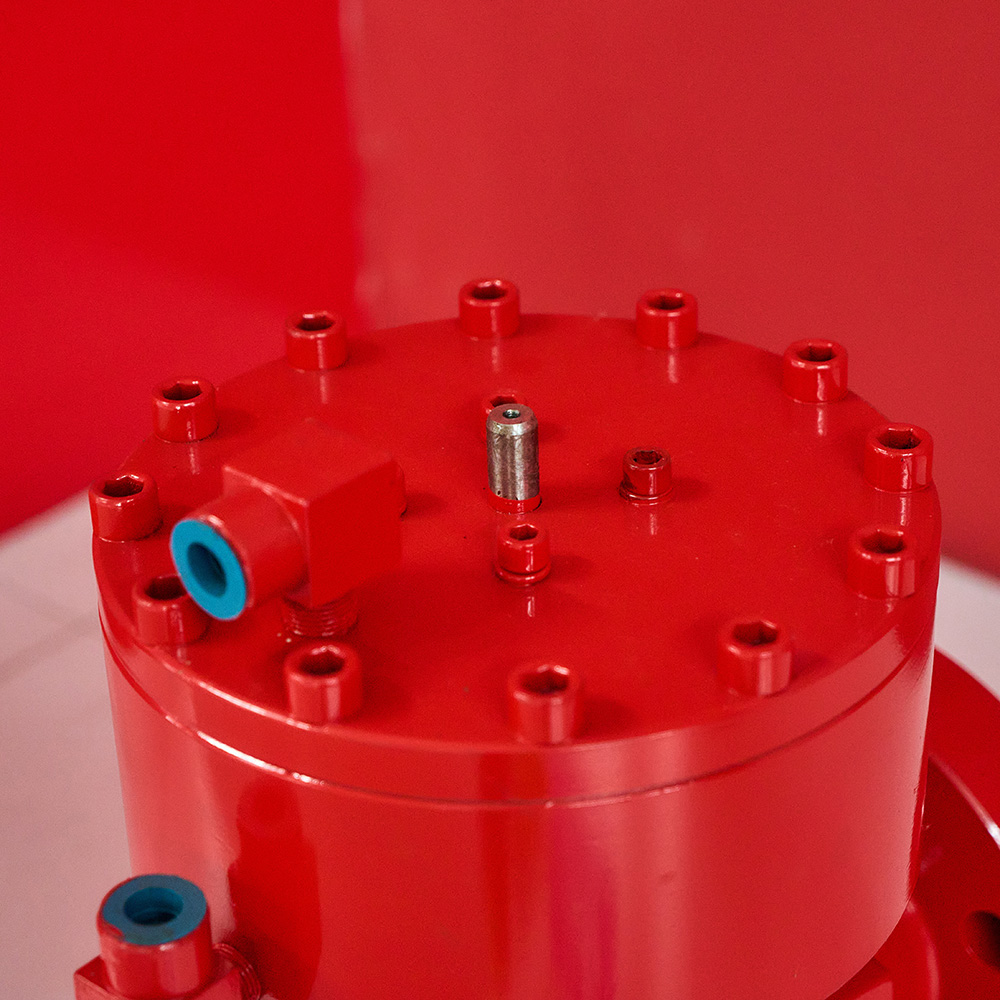

Hydraulic drive: The tail of the valve cover is a hydraulic cylinder and a piston. The piston is driven by hydraulic oil to drive the valve stem, and then the valve core is driven forward and backward.

Throttling control: The forward and backward movement of the valve core changes the flow area between the valve core and the valve seat, thereby achieving the purpose of throttling. When the valve core approaches the valve seat, the cross-section of the fluid channel flowing through the valve is reduced, forcing the fluid to accelerate through this reduced flow area. According to the Bernoulli principle, the increase in fluid velocity will cause its static pressure to drop, and then the pressure downstream of the throttle valve will be less than the pressure upstream, thus achieving flow control; conversely, when the valve core is away from the valve seat, the flow area increases and the flow increases.

Valve position feedback: In order to enable the operator of the control console to know the opening degree of the throttle valve, a valve position transmitter is installed at the outer end of the hydraulic cylinder of the valve cover. It can use the air pressure signal to transmit the actual switch position of the throttle valve core to the control console for display. The operator can remotely control the switch of the throttle valve through the control console.

The hydraulic throttle valve has good corrosion resistance and erosion resistance. The cylindrical valve core and the inner ring of the valve seat are made of hard alloy, and can be used upside down, which increases the service life. The larger valve body cavity and cylindrical valve body structure enable it to have a larger flow rate than the usual needle throttle valve. It adopts a side-in and straight-out flow direction, and the guide tube around the cylindrical valve plate reduces vibration and noise during throttling.

If you need, please contact us.

| Product name | Hydraulic throttle valve |

| Specification model | 2 9/16 |

| Implementation standard | API 6A |

| Rated working pressure | 15000psi |

| Product specification level | PSL1~PSL3G |

| Product performance level | PR1~PR2 |

| Temperature level | PU, LU |

| Material level | AA~FF |

| Product color | red |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jianhu Fulida Machinery Manufacturing Co. , Ltd.

- *Message:

-

Submit

Main Product:

Oilfield wellhead device,

Drilling and production equipment valve,

Blowout preventer,

Fracturing Manifold ,

Forged steel flange,

Forged parts of wellhead manifold

You May Also Like