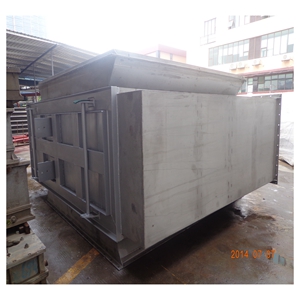

Jiema Plate type air to air heat exchanger

3 year agoAir Preheater in Thermal Power Plant Application

Air Preheater in Thermal Power Plant Application, also Preheater in Boiler or An Air Preheater, deals well with waste gas from the Industrial Tower/Power Plant. It absorbs the heat and passes it to another fluid. The transmission of energy thus takes place.

Our customer turns to us for an Air Preheater in Thermal Power Plant, and we recommend the Preheater in Boiler, also called An Air Preheater. It is designed by Jiema for toxic, harmful industrial waste gas recovery. Formed by a series of piling-up thin plates, it is characterized by stability, high transfer efficiency and low resistance. If you are looking for liquid-vapor heat exchanging equipment, this could be the right one for you! Contact us and enjoy more of its high heat transfer efficiency, few thermal losses, compact structure, small floor space, wide application and more to be found.

Industrial Methane Condensing Project from an Agricultural Chemical Company/

Toxic and Harmful Industrial Waste Gas Recovery

⛆ Plate Specification of Air Preheater in Thermal Power Plant(Reference Only)

|

Application |

Material |

Size |

Thickness |

Channel distance |

|

Waste Heat Recovery in Edible Oil Industry |

304, 316L,310S |

1200✖L mm (L is multiples of number 800) |

0.8-1.2mm |

10.8mm |

|

Heat Recovery in Boiler Fuel Gas |

304, 316L,310S |

750✖L mm (L is multiples of number 1860) |

1.5mm |

17.5mm |

|

High Temperature Fuel Gas Recovery |

Mostly 310S |

1200✖295 mm |

1.5mm |

10.8mm |

|

Mini-type Gas-Gas Recovery |

304, 316L,310S |

600✖L mm (L is multiples of number 800) |

0.8mm |

10.8mm |

|

Condensing in Chemical Industry |

304, 316L,310S |

1500✖500 mm |

0.8-1.2mm |

13.2mm |

|

NMP Recovery in Lithium Battery |

304, 316L,310S |

600✖600 mm |

0.4-0.6mm |

4-8mm |

⛆ Maintenance of Our Preheater in Boiler

1. Keep the cooling surface of An Air Preheater clean by blowing with compressed air or flushing with running water.

2. When the Air Preheater in Thermal Power Plant uses hot water as the heat medium, the hot water should be softened to reduce scale.

3. After the Preheater in Boiler has served for up to two to three years, clean its cavity with a chemical method to remove the scale in it.

4. When An Air Preheater is not running in summer, fully fill its cavity with water to reduce the rust in it.

⛆ FAQ of Air Preheater in Thermal Power Plant

1. What is the maximal temperature and pressure for Air to Air Heat Exchanger like Preheater in Boiler or An Air Preheater?

-20-800℃ and 0-1000KPa with huge-air-volume gas like air and flue gas.

2. Why Air to Air Heat Exchanger could be applied to Ultra-High Temperate Operation but Fin Tube Heat Exchanger could not?

The limitation of Fin Tube Heat Exchanger consists in its fin tube. Although it increase the heat transfer efficiency, the effect is realized at the expense of a thin fin which may break under extreme heat. On the other hand, our Air to Air Heat Exchanger doesn't have the worry and could perform its duty under high temperature. Take Preheater in Boiler for an instance, it will be doing well under 700℃ if using the suitable materials.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Guangdong Jiema Energy Saving Technology Co.,Ltd

- *Message:

-

Submit

Main Product:

Plate Heat Exchanger,

Shell And Tube Heat Exchanger,

Air Heat Exchanger ,

Water Chiller,

Shell and Plate Heat Exchanger,

Cooling Tower