LT75-4 Long life span linear actuator

2 year ago

Shenzhen Packway Technology Development Co., LTD, Founded in March 2005, has been at the forefront of innovation, constantly striving to develop cutting-edge technologies and solutions. We currently operate three subsidiary companies, each connected with different sectors of the machinery market.

History of the three branches.

Shenzhen Superworker Technology Co., LTD, established in June 2011, is an innovative enterprise specialized in industrial packaging. The main products and services include: automatic mechanical equipment (steel belt /PET belt strapping machine, clipping belt machine, marking spray machine, labeling machine, etc.), intelligent industrial packaging unit (coil, wire, plate, etc.), intelligent coil logistics system, transformation and upgrading services of similar products, repair and maintenance services of related equipment, supply of wearing parts and consumables. The SUPERWORKER has strong R&D strength and Customers from both domestic and international markets.

Shenzhen Dagongren Electric Cylinder Technology Co., Ltd came into being in 2014. We are engaged in designing and manufacturing linear motion products, including servo/stepper motor electric cylinders, linear actuators, multi-degree of freedom platforms, synchronization lifting platforms, VR simulators, etc, with features of high positioning accuracy, low noise, and long life. Our products have been widely used in automated warehousing, robotics, automation equipment, medical equipment, and AGV, vehicles, etc.

Works Hydraulic Technology (Dongguan) Co..Ltd, deeply rooted in the hydraulic, electronic control, and mechanical related industries, focuses on the research and development, production, and sales of electromechanical and hydraulic products. With a professional approach to providing personalized solutions for customers as the main model. Works mainly produces various Hydraulic Equipment, lubrication equipment, electronic control systems, hydraulic cylinders, and other products.

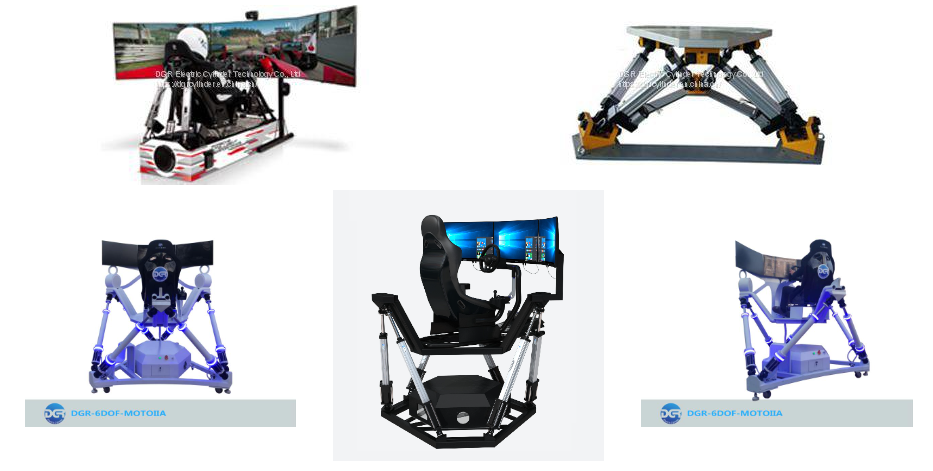

DGR-6D Introduction

6-axis motion platforms(Virtual Reality Platform) offer a number of advantages, including:

Appearance

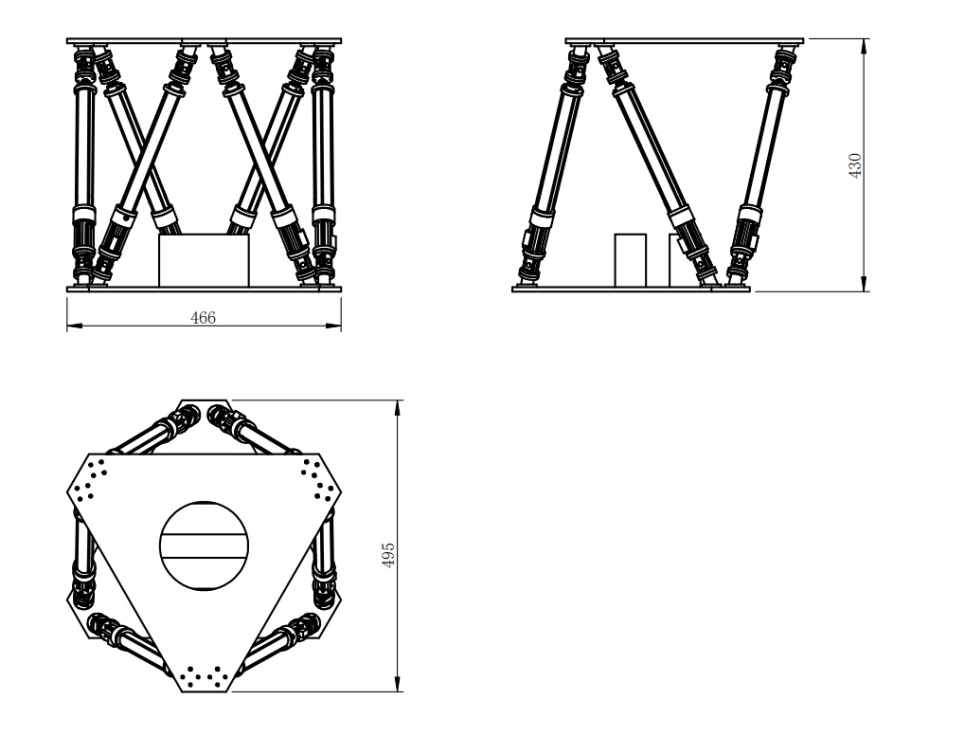

Dimensions

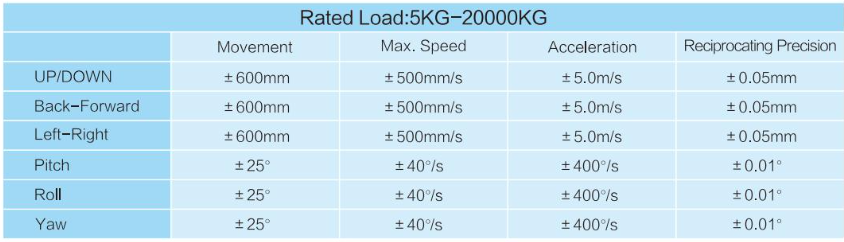

Technical Specifications

Control System

A. The control system of the 6D of freedom simulation platform includes:

HS servo driver, Mbox motion controller, industrial computer, electrical cabinet, connecting cables, etc.

B. The main functions of the HS servo driver include:

1. CAN bus motion control function: position/speed/torque control, mode switching.

2. Fast current loop floating-point CLA kernel processing with good dynamic tracking performance.

3. RS485 communication interface supporting MODBUS protocol, directly communicating with upper computer and touch screen.

4. Support CAN bus interface, built-in proprietary communication protocol, convenient for customer customization and use.

5. The control port supports software allocation, logical settings, and programmable filtering, making it flexible, convenient, and reliable to use.

6. Two analog outputs can observe the internal status of the driver, facilitating on-site debugging.

7. Built in electromagnetic brake control, providing logical and rigorous fall safety protection for the dynamic platform.

C.The main functions of the Mbox motion controller include:

1. The Ethernet interface is used for communication connections, with strong scalability and simple on-site wiring.

2. Equipped with a 6-way ADC input interface, it is compatible with the upper controller WffiS to achieve DAC board mode motion control.

3. 12 digital outputs, supporting parameter programmable digital special effects control.

4. 2-way analog output, supporting continuous and delicate simulation of specific control.

5. Multifunctional application of 8-channel digital input and other signal interfaces.

6. The application supports fully infinite switch mode, and the upper limit supports soft limit.

7. Easy to monitor and diagnose, with RS232 for local monitoring of motion control.

8. Networking is convenient and flexible. Single groups of motion control form the entire system through Ethernet, and all single groups can achieve the expected designated motion control in an overall, row group, column group, or point group manner. RS232 interface is provided for external expansion of all devices that support MODBUS communication protocol.

Note: The above data is for reference only, and corresponding non-standard designs can be made according to the actual needs of customers.

Packaging & Shipping

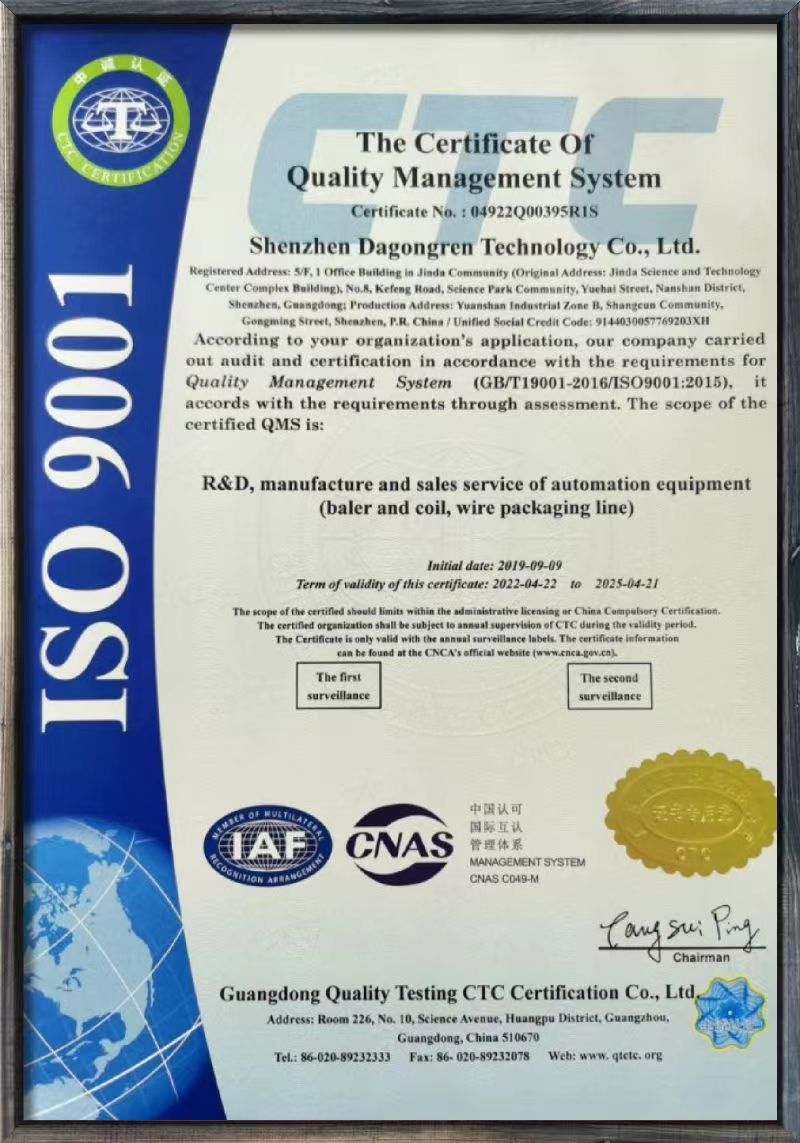

Certifications

FAQ

Q1. What are your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown wooden cartons. If you have a legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What are your terms of payment?

A: T/T 50% as deposit, and 50% before shipping. We'll show you the photos of the products and packages before you pay the balance.

Q3. What are your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 10-25 days to produce the products. The specific delivery time depends on the items and the quantity of your order.

Q5: How is the warranty system?

A: 1~5 years. (upon the deal)

Q6. Do you test all your goods before delivery?

A: Yes, we have a 100% test before delivery.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen Packway Technology Development Co., LTD

- *Message:

-

Submit

Main Product:

electric actuator ,

hydraulic cylinder,

coil strapping machine,

Steel coil production and packaging unit,

Fully automatic steel pipe stacking production and,

equipment and system solutions for steel coil logi