240913cantilever welding robot

4 month ago

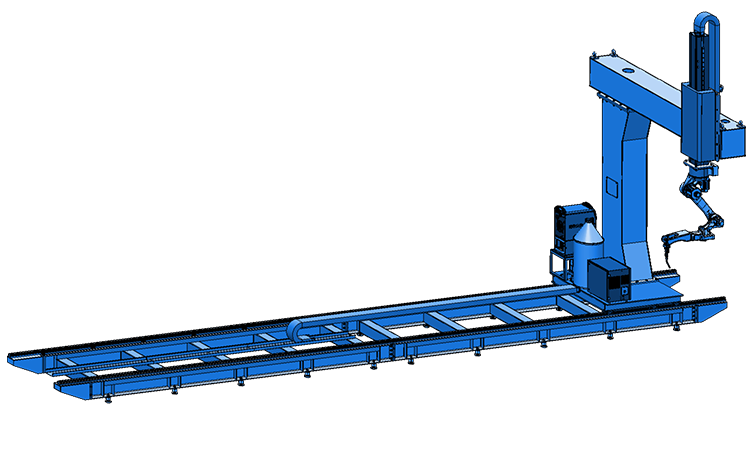

At present, it is mainly used for the welding of H beam steelordinary reinforcement plate, transverse reinforcement plate, column bottom plate, purlin support plate, corbel and other structures.

The advantage of the cantilever type is that the workpieces can belifted to the workstation in batches, saving lifting time.

|

Robot

|

MR12-2010

|

|

Welder

|

Aotai/Megmeet

|

|

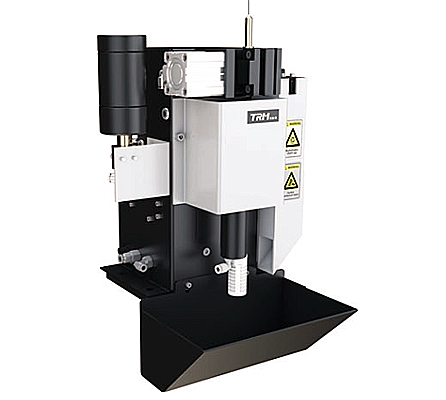

Welding gun

|

TRM water-cooled extended welding gun

|

|

Control system

|

Friendess teaching-free welding system

|

|

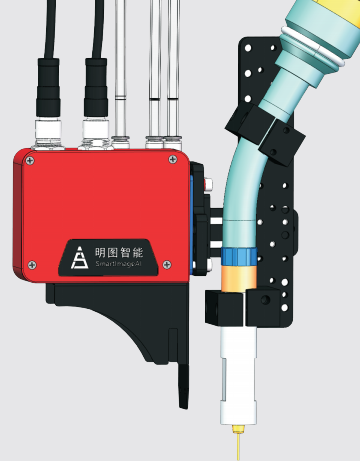

Vision system

|

Friendess large viewing distance sea m finder

|

|

Rail

|

12m(length can be customized)

|

|

Application scenario

|

secondary processing for steel structure

|

|

Machine spec

|

(7 axis)ZX-XRYH100

(8 axis) ZX-XRYHSW100

|

|

Total power

|

(7 axis) Robot 10KVA +welder 31KVA

(8 axis) Robot 13KVA+welder31KVA

|

|

Max. operating range

|

(7 axis)10m×1.3m×0.4m(12mground rail)

(8 axis)10m×1.3m×1.2m(12m ground rail)

|

|

Average welding efficiency

|

0.3-0.5m/min(different weldingprocess, different speed)

|

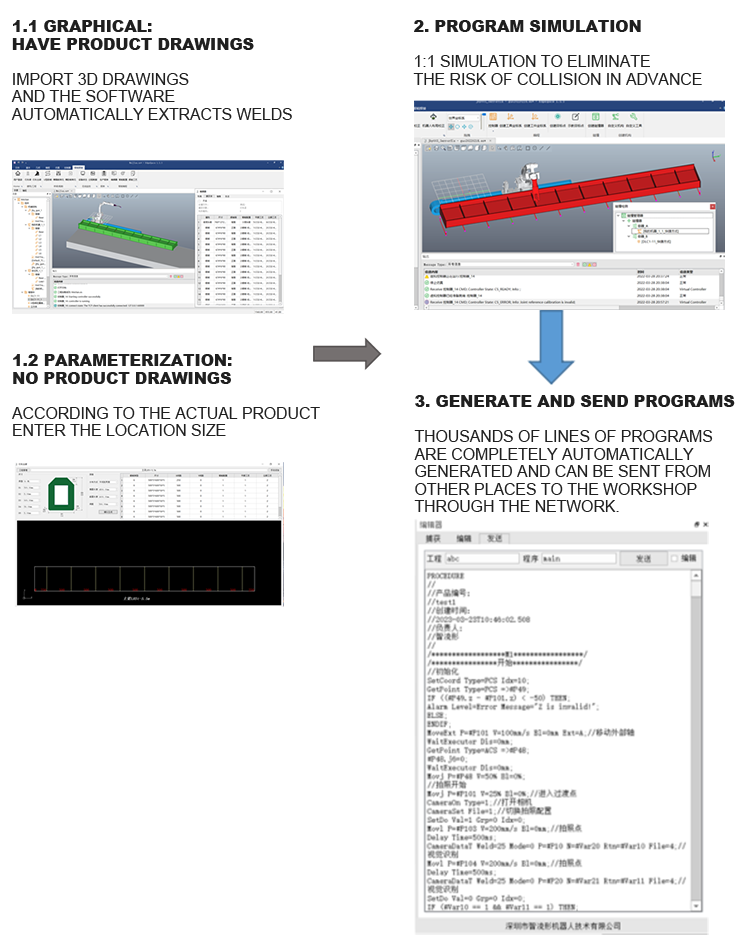

Robot Operation Process

processing and welding seam identification functions are completed inside the sensor without the need for an external computer. It

has high integration and reduces the overall hardware cost of the system. Resistant to arc light and spatter, intelligently

identifies weld seams, and is easy to operate. It has an exquisite structure, compact size, high accessibility, and rich types. It

can be selected and used according to the application scenario, and the most suitable parameters can be customized. Factory Supplies

the welding gun during robot welding, automatically cut wires, and protect the welding gun nozzle and contact tip, extending the service life of the welding gun and saving money. Reduce consumable costs, maintain good welding quality, and improve welding

efficiency. Simple operation and easy to use.

Advantages of gun cleaning stations: 1. The gun clearing time is short and the system availability is high. 2. Automatically

complete the gun cleaning process without manual operation. 3. Prevent quality problems caused by contamination during welding. 4.

Equipped with robot TCP calibration needle.

Robot welding software

Advantage

1.Supports teaching-free for various products such as sandwich panels, truss beams, bracket , bridge partitions, and panel stands;

2.There is no need to mark welds at the design stage, and the target weld position can be automatically extracted by importing 3D drawings;

3.No human intervention is required, the robot automatically completes actions such as zero return, transition, position finding, welding, counting, and gun cleaning;

4.No on-site operation is required, the program can be generated at any time and place, and remotely sent to the robot for

production according to the specified time;

5.Self-developed offline programming, 1:1 simulation of robot movements, avoids robot interference in advance and avoids collisions;

6.Digital twin technology can display on-site robot trajectory, welding voltage, current, speed and other production information in real time.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Wuxi Zhouxiang Complete Set of Welding Equipment Co., Ltd.

- *Message:

-

Submit

Main Product:

H Beam Welding Machine,

H Beam Assembly Welding Straightening Machine,

H beam Horizontal Productions Line,

Box Column Productions Line,

Automatic Assistant Welding Machine,

Street Lamp Post Productions Line